Riveted Chains

Riveting is a mechanism of fixating two plates or objects together via one or more rivets; where a rivet is a permanent mechanical fastener, cylindrical in shape. Riveting is achieved by placing the rivet at a desired place and the end(s) are hammered down.

LPG plants typically use riveted chains. Chain links are assembled together via a pin that is riveted on both sides. When installing a new bottling plant, specialized tooling is brought to perform riveting operation. Since the plant is not started, there is no LP Gas in the environment, and thus, no safety risk with riveting operation. However, the story is completely different when replacing the riveted conveyor chains.

Replacing Riveted Chains

Conveyor chains need to be replaced in an LPG Bottling plants for couple of reasons. It is possible that chain is being replaced due to scheduled maintenance practice, wear & tear or in case of chain breakage.

For any of the above cases, replacing riveted chains require the plant to be completely shut down. Specialized tools are brought in to perform riveting on site. LPG bottling plants have many hazards. The shutdown is to ensure no hazardous situation occurs during the riveting process. However, the LP Gas can still remain in the air for longer duration, and create a hazardous situation.

Replacing riveted chains in wet or dry LPG Bottling plants can result in:

- Loss of production / plant down time

- Risk of Sparking and associated fire hazard

- Cost associated with procurement and maintenance of riveting tools.

- Dependency/Cost with specialized skilled labor to perform riveting operation.

Riveted chains are always shipped in small batches depending (for example 5 or 10 meter length). Thus, when replacing 500 meter or 1000 meter segments in a LPG Bottling plant, multiple riveting operations with a specialized riveting tool needs to be performed, further increasing operational time and cost.

Rivetless Chains

At Jasma, we have developed M-series rivetless chain (Design Patent). These chains eliminate all the issues with riveted chains, and make installation as well as replacement quick and easy.

No special tooling is required to connect the chain links. Elimination of special tooling reduces cost associated with riveting tools, labor and risk with sparking. Moreover, when replacing a section or entire line of the conveyor, any worker can quickly uninstall and install the chain links without any prior training.

The rivetless chain by design will not come out in a running plant. The pins only come out (from one side) when two chain links are positioned to form a 90-degree angle, which can never occur in a conveyor track. Checkout our blog on benefits of dry (rivetless) chains.

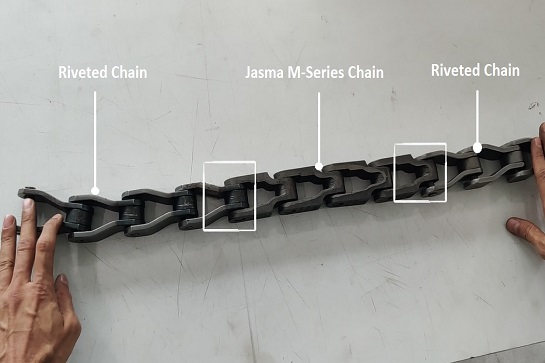

Compatibility between Riveted & Rivetless Chains

Due to the advantages of rivetless chain over riveted chains, many of our customers have repeatedly chosen Jasma M series rivetless chains. Customers have either completely replaced riveted chains in their LPG bottling plants, or only replaced a section of the plant. No issues have been reported till date. Jasma chains are backward compatible with riveted chains used in both dry and wet bottling plants.

Our chains are out of the box compatible with riveted chains without any need for tooling’s or adaptors without any compromise on functionality and performance. The image on top of this blog shows how Jasma rivetless chains seamlessly fits with the riveted chains.

Jasma supplies both riveted and rivetless chains to 45+ countries across the globe.